By Axel Boilesen, February 2013

Chris Boilesen, my Dad, had

many talents as builder and inventor. On our farm where I

was born and grew up near Cotesfield, Nebraska, the barn and

his blacksmith shop were areas that saw alot of activity and

many successful projects.

The Farm's Blacksmith Shop

I doubt if the shop area was

more than 16 feet by 16 feet but it contained a forge, a hand-cranked

post drill, a large workbench, a large anvil, vice, tool chest,

stock of angle iron and pipes of various diameters and lengths

and many other raw materials that he salvaged and collected

over the years into small junk piles adjacent to the blacksmith

shop. My Dad knew the resources he had to work with and I

believe he had plans in his mind well in advance to starting

each project based on what he had to work with and how it

would all come together.

I admired his creativity. And

the amazing thing was that it was all in his mind without

any preliminary drawings.

Water System

An early example of his creativity

was the water system he created for our home and for the livestock

on our farm. We had a tall windmill, probably 50 feet high,

with a forced pressure cylinder. The windmill was approximately

50 feet from the house. The layout of the water system was

as follows:

A new galvanized pipe was installed

from the windmill to the pantry (well below frost depth) and

that pipe was connected to a cubical storage tank about 3'

by 3' by 3' which was mounted in the ceiling of the pantry.

As part of the system when the kitchen tank was full, an overflow

pipe would discharge the excess water back outside to a horse

tank with a similar overflow system that took the water into

a cystern with piping to the hog yard and additional valves

to the cattle feed lot.

This water, pipe and temporary

storage system provided fresh cold water to the kitchen and

washroom year-round. We did not have electricity on the farm

until many years later but continuous fresh drinking water

was quite a treat. The system was fully automatic and relatively

maintenance free.

Ensilage System

Another system that I'll always

remember my Dad for was the system in the barn that he developed

for feeding ensilage to the milk cows. I'm guessing the size

of the pit silo for storing the fodder was about 15 feet in

diameter and 25 feet deep. The pit silo was adjacent to the

north end of the barn and had a shed type roof. Ensilage was

stored in this pit and the ensilage cutter to produce the

fodder was a production it itself using an old Republican

truck with a belt and pulley system as the power source. The

silo had adequate capacity to last most of the winter.

This takes me to the ensilage

system itself. Once the silo was filled the fodder needed

to get to the cows. It was this system for bringing the ensilage

through the opening in the barn and depositing it at the head

of the milk cows that I still marvel at.

The system consisted of steel

cable, pulleys, much angle iron to serve as trackage, a steel

box about 4' by 4' by 4', and more angle irons and pulleys

to connect the large carrier box to the lifting device. The

process was to lower the box unit into the pit silo, fill

the box and lift the filled unit of ensilage with a winch

assembly made up of pulleys, cables, steel drum, and a large

2 foot long crank to give added leverage. Added features were

included to control the pulley on the box for access to the

angle iron track. My Dad had the unique ability to visualize

the added features to make it work. And by creating such a

system it saved all of us alot of work, eliminating the need

to carry by ensilage by hand.

Gutter System

A mechanical system that again

took advantage of our farm's blacksmith shop and scrap iron

was the sytem my Dad constructed to clean the gutters built

into the floor just to the rear of the cows. The hauling device

was like a half barrel with linkage to a track. The cart part

was commercial and my Dad's part was building the track and

cable system to transport the loaded units with a tripping

device to empty the contents over a manure pile 50 feet beyond

the back of the barn.

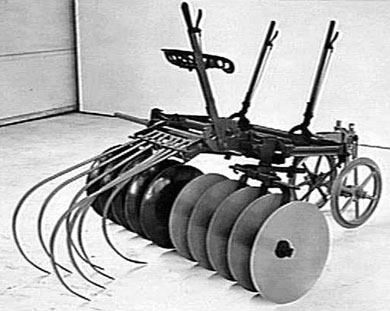

Modified Disc Machine

I've always thought this farm

implement modification that my Dad made was worthy of obtaining

a patent as its function was to store rainwater as well as

allowing minimum tillage which is so popular even up to today's

farming methods. In case you weren't raised on a farm, a disc

or disc harrow is a farm implement that cultivates the soil.

You disc before you plant but it can also be used to weed

and after the crops have been harvested to chop up what is

remaining from the plants.

In the 1920's we had a disc

that was pulled by a team of 2 horses and even when I was

old enough in the 1930's to work in the fields we still used

horses to disc our fields where we were trying to grow corn

and hay. Discing wasn't always a good thing and I can remember

what seemed like many endless hours going back and forth across

that land and discing those dry hills that had hardly seen

a drop of rain the whole season and wondering what was the

point. Looking back at those Great Depression years in general

discing probably did contribute to the Dust Bowl when no rain

and no crops could not prevent the soil from being blown away

by the wind. But each year we would start the cycle again

and hope for rain and hope for things to get better. So in

that context my Dad's spirit of inventiveness was partly survival,

partly hope but certainly noteworthy for his creativity and

resourcefulness.

My Dad's modification started

with a standard disc approximately 12 feet in size. The standard

disc was round and shaped like a dish or saucer. The outside

diameter was approximately 18 inches with a square hole for

the shaft approximately 1 1/2 inches in size. The square shaft

kept the large discs all rotating as a unit with spacers between

each 18 inch disc spread at least 9 inches apart.

His modification was to cut-out

a pie shaped wedge of approximately 1/4 the projected area

of the disc leaving each disc as approximately 3/4 the original

circle. The notched out discs were then reassembled on the

square shaft, each one being a quarter circle ahead of the

previous cut-out disc.

The performance was exceptional.

We called it the waffle disc because when the field work was

completed the field surface looked like one huge waffle.

What could be better to prevent

excess runoff and soil erosion? Of course rain was essential

for farming and for this modified disc to really have a chance

to fully demonstrate its advantages we had to survive the

drought of the 1930's during which time we did lose our farm.

But even after we lost our farm we moved a few miles away

and were farming again the next year.

Eighty years later I have still

not seen anything quite like it. Simple vision of making a

good thing better and all in just a crude blacksmith shop.

A sad part of this story is

that I never took the time to tell my Dad that he had a good

mind and mechanical vision that his family can always be proud

of.

A somewhat smaller

version of the disc machine modified by my Dad.

Chris and Elizabeth Boilesen

family portrait, approximately 1943, Cotesfield, NE; Back

row left to right Fern, Floyd, Axel, Lester; Front row left

to right Garold, Parents Elizabeth and Chris Boilesen, Lois.

The original Chris Boilesen

homestead barn as seen in 2013 approximately 100 years after

it was built. The house and blacksmith shop are no longer

standing nor are the other 'systems' that were developed in

the 1920's and 30's by Chris.

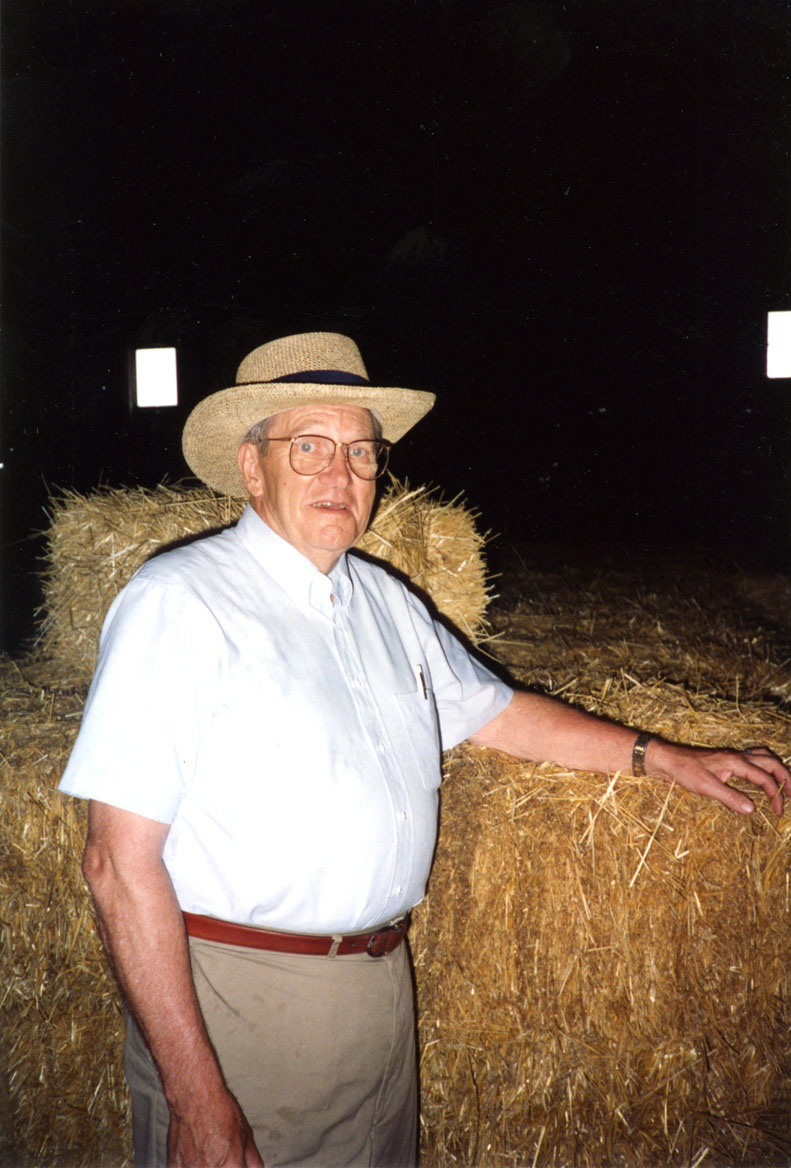

Axel visiting

original barn circa 1988